Honda Announces $210 Million Eco-Friendly Vehicle Paint System

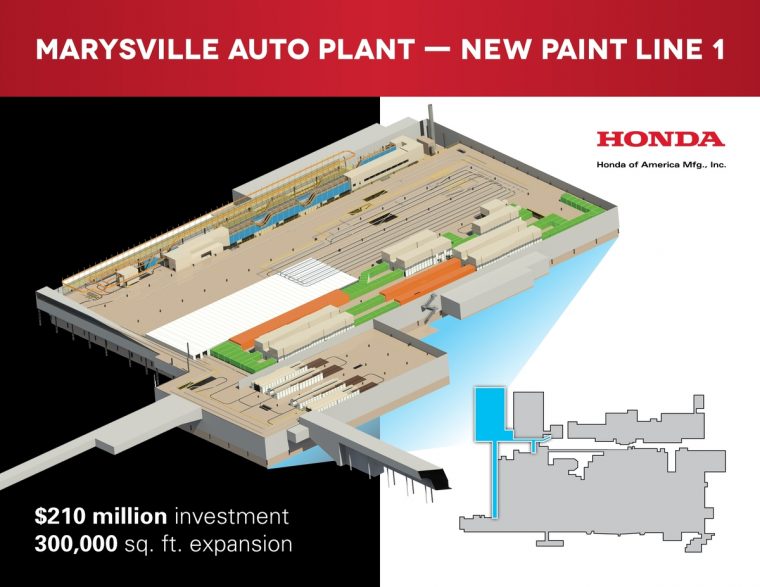

Today Honda of America Manufacturing, Inc. announced a $210 million investment in a new vehicle paint line at its Marysville, Ohio plant.

The new Marysville Auto Plant (MAP) Line 1 paint facility is scheduled to open in December 2017, at which point it will become the most energy-efficient paint line in the Japanese automaker’s US vehicle production network. New technologies will enable the plant to reduce energy use, water use, and chemical emissions that are part of the painting process.

“Honda is committed to delivering products that have outstanding quality and low environmental impact,” said Honda of America Mfg., Inc. COO Tom Shoupe. “With this new investment, our Ohio operations are once again raising the bar for quality and environmentally responsible manufacturing operations.”

Honda currently uses a 4-coat, 3-bake process, but will be eliminating one primer-coat curing oven for the new paint shop’s more efficient 4-coat, 2-bake short process. A 2K waterborne primer designed exclusively for Honda will facilitate the shorter process, and, when combined with a waterborne base coat, will reduce volatile organic compounds emissions by nearly 66%.

The new paint line will also utilize “dry-booth” technology, which uses limestone dust instead of water to catch paint overspray. The change should reduce water usage at the plant by two million gallons annually, and will also eliminate over 255 tons of paint sludge, a waste byproduct of the current system. CO2 emissions will also be cut down by 18%, or 12,000 metric tons annually.

The News Wheel is a digital auto magazine providing readers with a fresh perspective on the latest car news. We’re located in the heart of America (Dayton, Ohio) and our goal is to deliver an entertaining and informative perspective on what’s trending in the automotive world. See more articles from The News Wheel.