On the off-chance that you recently emerged from a multi-year hibernation or a block of ice, I’ll let you in on a not-so-secret secret: The world isn’t in the best shape right now. A lot of it has to do with everybody’s favorite global health crisis, a variety of political factors, and poor environmental conditions. Unfortunately, the auto industry isn’t immune. One of the more recent symptoms is a widespread shortage of computer chips that’s disrupting everything from the production of vehicles to the availability of video game consoles. Here’s what that’s all about.

High-tech and hardcore: The 2021 Chevrolet Silverado 2500

What are chips?

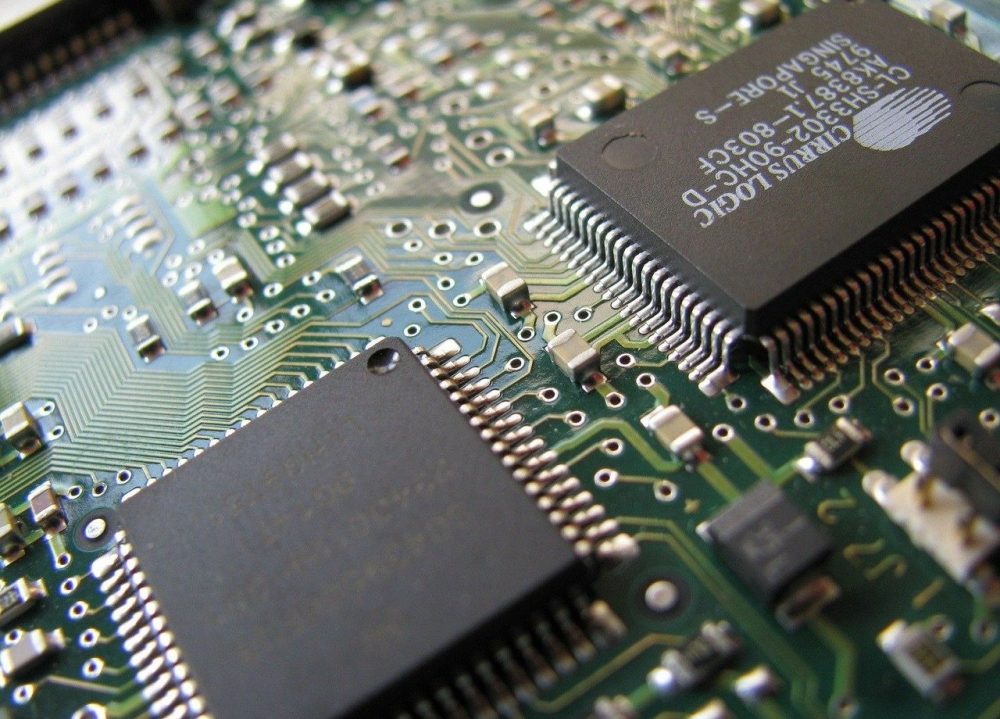

Before diving into the issue at hand, it’s worth understanding what chips are and what they do. According to Britannica, chips are “integrated circuit[s] or small wafer[s] of semiconductor material embedded with integrated circuitry” that “comprise the processing and memory units of the modern digital computer.”

In layperson’s terms, they’re the things that make all of your devices run. Different types perform different functions, ranging from transmitting simple commands to processing complex information to modulating power. If you’ve been in a car recently, you know that they rely heavily on computers for just about everything. In essence, if you don’t have chips, you don’t have a vehicle.

How did this happen?

Depending on who you ask, you may get a different answer as to why the world is suddenly so short on chips. As best I can tell, the reality of the situation is most likely a combination of factors. The first, unsurprisingly, is the COVID-19 pandemic, which slowed production to a crawl. There’s also the issue of shaky trade relations with China, where a sizable portion of chips is manufactured.

The Verge’s Chaim Gartenberg also believes that poor timing, the increasingly electrified nature of pretty much everything, and a higher demand for computerized products during lockdown contributed to the issue. To top things off, Debby Wu and Takashi Mochizuki from Bloomberg state that the winter storm that smashed into Texas in February and a factory fire in Japan will extend the shortage.

What does it mean?

The prognosis for the auto industry is a mixed bag. The bad news is that the crisis has already forced numerous carmakers to slow the development of new vehicles, and some experts say that we won’t see the light at the end of the tunnel until some time in 2022 at the earliest. It’s also raised demands for chips, which has forced some automotive brands to temporarily increase prices to compensate for higher production costs.

But there is good news, too. To start, President Joe Biden recently met with multiple members of the automotive industry — including power-players like GM — to work on a solution. He also signed an executive order designed to increase the production and distribution of semiconductors in America.

The other silver lining is the fact that, despite limited resources and slow assembly lines, people are still buying cars. Plus, the pandemic-related concerns that surround public transportation are converting more and more commuters to car owners. There’s a conversation to be had about the environmental impact of that shift, but that’s a topic for another time.

Ultimately, the industry will do what’s done before — adapt, innovate, and move on. If cars ever go kaput, I doubt it will be the fault of a computer chip.

Drive confidently into the future: On a quality set of tires

Additional sources: Brian Sozzi – Yahoo Finance, Whitehouse.gov, Che Pan – South China Morning Post

The News Wheel is a digital auto magazine providing readers with a fresh perspective on the latest car news. We’re located in the heart of America (Dayton, Ohio) and our goal is to deliver an entertaining and informative perspective on what’s trending in the automotive world. See more articles from The News Wheel.