The 2022 Chevrolet Silverado 1500

The 2022 Chevrolet Silverado 1500

Photo: Chevrolet

An ongoing microchip shortage has caused delays in the release of many vehicles. Rather than pausing production of its models completely, General Motors has been continuing to make partially complete Chevrolet Silverado and GMC Sierra trucks at the Fort Wayne Assembly plant. Then, it has been storing these models at the Kokomo, Indiana, plant until microchips arrive.

Check Out the Latest Silverado: An overview of the 2021 model

The 2021 GMC Sierra 1500

The 2021 GMC Sierra 1500

Photo: GMC

The Kokomo plant has 2.6 million square feet of space, including a massive parking lot. Accordingly, it can fit thousands of pickups — potentially up to 7,000 — as they wait for microchips and other electronic parts.

This allows the Fort Wayne Assembly plant to stay up and running. And it means that the GM will be able to ship the trucks to dealerships soon after receiving the chips. If GM were to instead pause production until it has all the parts it needed, this could potentially lead to an even longer wait for dealers.

Other GM facilities around the country have also been producing models despite parts shortages, leading GM to stockpile models at Michigan State University, in parking lots in Texas, and at many GM plants.

The irony of choosing the Kokomo plant as one such storage location is that it once manufactured the very same chips that GM now desperately needs. It stopped producing them in 2017 because it didn’t have the equipment to compete with suppliers globally. These same suppliers may not be able to fulfill the demands of automakers until 2023.

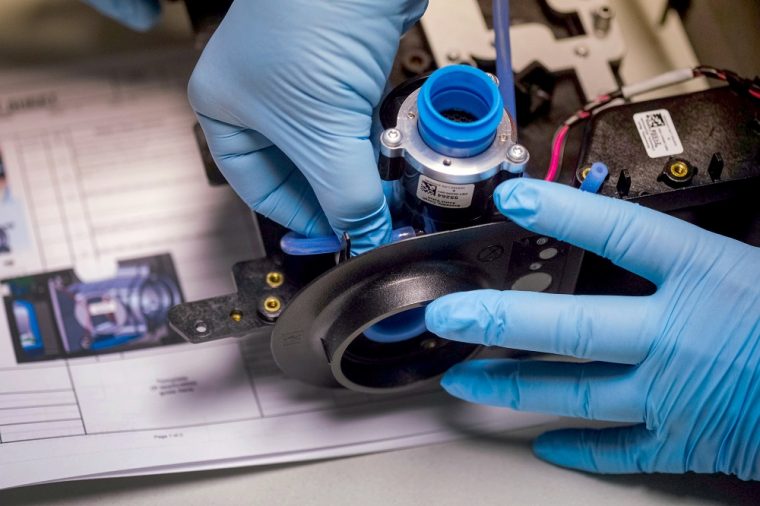

A Ventec ventilator being made

A Ventec ventilator being made

Photo: AJ Mast for General Motors

Unfortunately, the Kokomo plant no longer has the equipment to make any chips. GM would need to start from scratch if it wanted to begin production again. Last year, GM worked with Ventec Life Systems to manufacture ventilators here for hospitals, and the location has since just served as extra storage space.

Since the global chip shortage doesn’t look like it will be going away anytime soon, dealers will likely continue to have low inventories of new cars as well as unusually high-priced used cars for the near future. However, if GM’s strategy pays off, its dealers may at least be able to stock up faster than others.

Amanda Drago lives in West Chester, Ohio with her wonderful family, which includes her adorable dog, Coco. Amanda recently graduated from Miami University with degrees in both marketing and creative writing. However, if she was ever forced to change career paths, she imagines that she would train dogs for movies. In her spare time, she enjoys reading, writing, and watching Netflix. She also has a special place in her heart for theatre and purchases tickets to as many shows as she can. See more articles by Amanda.