Volkswagen has announced the opening of a new battery production facility in Germany, a move expected to dramatically reduce the cost of its upcoming models. With the launch of four new electric city cars planned for 2026, including the Volkswagen ID. Polo, ID. Cross, Cupra Raval, and Skoda Epiq, Volkswagen is focusing on cutting-edge battery technology to make EVs more accessible while improving performance.

At the core of this new approach is Volkswagen’s focus on reducing the price of EVs by increasing the efficiency of their batteries. The new factory, located in Salzgitter, Germany, will produce an innovative unified battery cell that promises better energy density and flexibility. According to Volkswagen, these new cells are set to boost energy density by 10% over the current generation, which could significantly reduce costs across its upcoming lineup.

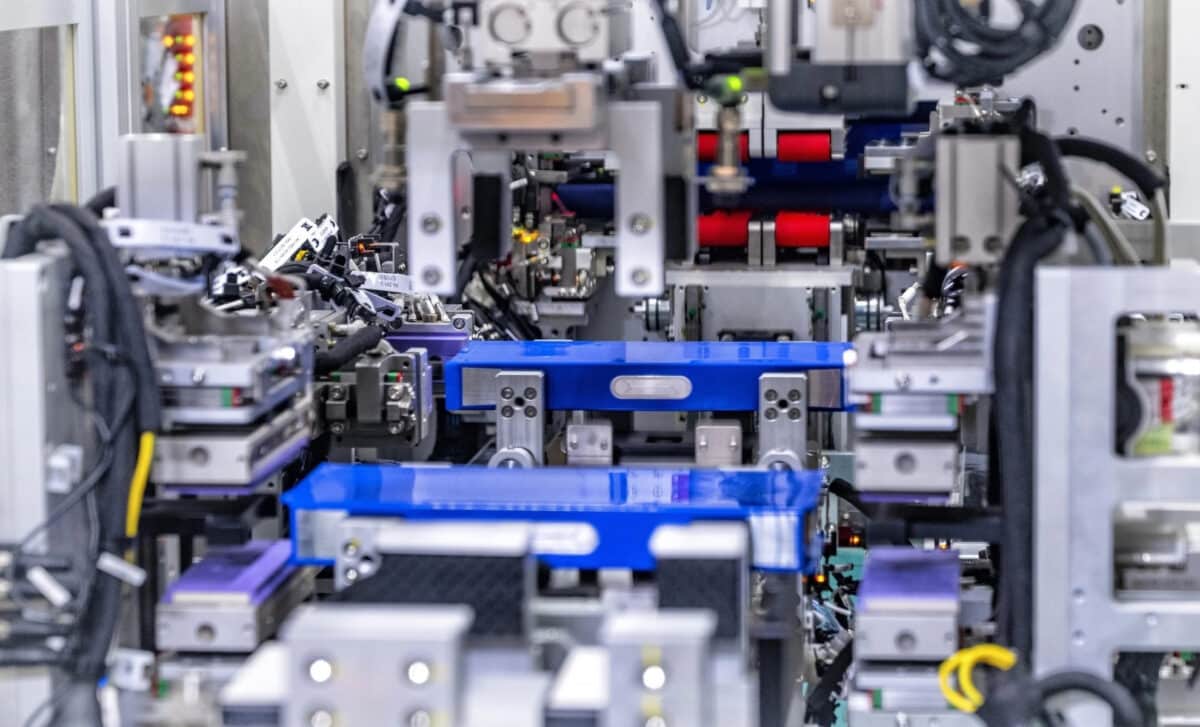

A Game-Changing Battery Plant

Volkswagen’s investment in a state-of-the-art battery production facility marks a key step in the company’s shift to electric mobility. The plant in Salzgitter will produce PowerCo’s new unified battery cells, designed to accommodate all types of battery chemistries, making them highly adaptable for various applications. The first phase of production will focus on NMC (nickel, manganese, cobalt) battery cells, which will have an energy density 10% higher than current batteries.

The factory’s production target for its initial phase is 20 GWh annually, enough to supply around 250,000 electric cars. Volkswagen’s long-term goal is to increase that to 40 GWh per year. While the company is also working on developing cheaper LFP (lithium iron phosphate) cells, these will initially be purchased from external suppliers before eventually being produced at the Salzgitter facility.

Advantages of Localized Battery Production

Volkswagen’s decision to produce batteries in Europe is strategic in several ways. Not only does it enable the company to gain greater control over production and costs, but it also allows the new electric vehicles to qualify for local government subsidies. In countries like France, electric vehicles with European-made batteries are eligible for a “surbonus,” a financial incentive that could further lower the price of Volkswagen’s upcoming models.

Additionally, this move is a response to the challenges of global supply chains. The instability caused by external factors such as raw material shortages and geopolitical tensions has highlighted the importance of localizing production. By securing its own supply of batteries, Volkswagen aims to reduce its dependence on foreign markets and create a more stable and reliable production pipeline for its EVs.

Aiming for Affordable and Efficient Electric Cars

Volkswagen’s upcoming range of small electric vehicles is designed to be both affordable and efficient. The ID. Polo, ID. Cross, Cupra Raval, and Skoda Epiq will feature the new unified battery cells and benefit from the efficiencies achieved through local production. According to Volkswagen, these advancements will result in better performance, longer driving ranges, and lower prices compared to many current electric models.