Backed by a new agreement with Sumitomo Metal Mining Co., Toyota is working to finalize the battery materials needed to launch what it hopes will be the world’s first practical BEV with this architecture.

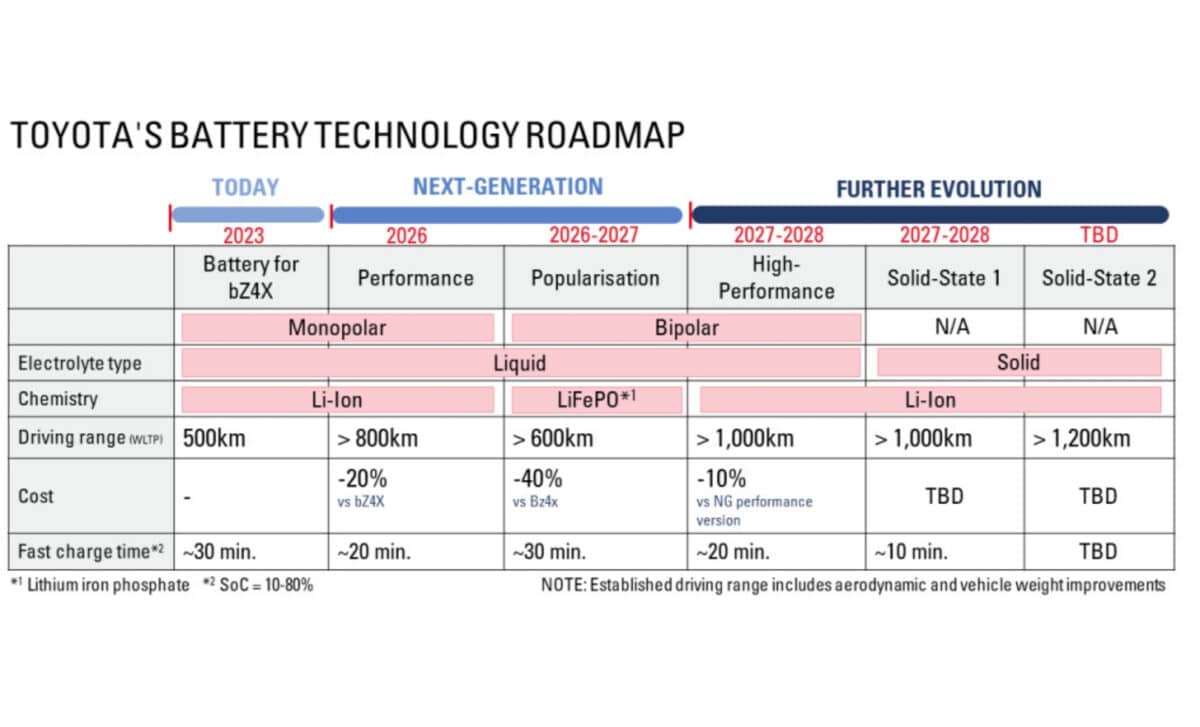

The project marks a turning point in Toyota’s electrification strategy. After years of trailing behind other automakers in the EV race, Toyota is now betting heavily on a technology that promises higher energy output, faster charging, and longer battery life—all in a smaller and potentially safer package. Japan’s broader effort to secure a domestic supply chain for battery components also plays a central role in the initiative.

Toyota’s announcement comes amid a crowded field of competitors, each racing to be first to market with solid-state batteries. Whether Toyota leads the pack or not, the company is building a network of industrial partnerships that could speed up its timeline and stabilize long-term production.

Toyota and Sumitomo Push Cathode Innovation

A central piece of Toyota’s plan is its collaboration with Sumitomo Metal Mining Co., which was formalized this month to support the mass production of advanced cathode materials. The two companies have been working together since 2021, targeting technical barriers that have so far prevented solid-state batteries from reaching mass market readiness.

Sumitomo’s contribution lies in its powder synthesis technology, which Toyota says has resulted in a “highly durable cathode material” suitable for solid-state batteries. Unlike traditional lithium-ion systems that rely on a liquid electrolyte, Toyota’s solid-state design replaces that component with a solid electrolyte, enabling compact battery architecture with higher output.

According to Electrek, the development brings Toyota closer to its goal of commercializing the battery within the next two to three years. The new material is expected to enhance performance while also extending the battery’s life cycle—a key requirement for real-world EV use.

Domestic Battery Supply Chain Under Construction

The push toward all-solid-state batteries isn’t just about performance—it’s also about securing industrial autonomy. Toyota and its Japanese partners are investing heavily in local production, with a combined total of $7 billion earmarked for domestic battery initiatives. This includes everything from raw materials to finished battery packs.

Among those partners is Idemitsu Kosan, which earlier this year announced it would build a large-scale plant dedicated to producing lithium sulfide, a raw material essential for solid electrolytes. Once operational, the plant is expected to produce 1,000 metric tons annually. Toyota is also working with Idemitsu to align production capacity with its vehicle development schedule, reinforcing Japan’s attempt to reduce dependence on Chinese and South Korean battery suppliers.

As reported by the same source, Toyota received METI certification last year to begin manufacturing its new battery systems in Japan. This regulatory milestone allows the company to prepare its domestic facilities for eventual scale-up as soon as materials and designs are locked in.

Global Competition Intensifies

Toyota’s claim to being first with a commercial all-solid-state EV is already being challenged. Mercedes-Benz said in February it had successfully tested a vehicle equipped with lithium-metal solid-state batteries, which managed to drive 750 miles (1,205 kilometers) on a single charge. The company’s tech chief described the achievement as a breakthrough, and Mercedes aims to bring the batteries into series production by decade’s end.

Other players—including BMW, Volkswagen, Honda, CATL, and BYD—are also moving forward with solid-state programs, many of which have 2027 or 2028 as their target dates. Meanwhile, SAIC MG introduced a semi-solid-state EV, the MG4, into mass production in August, further blurring the lines around who gets to claim the “first.”

Toyota has spoken publicly about solid-state technology for years without delivering a product, raising some skepticism. But the latest agreements and certifications point to real progress.