Honda Aero Burlington Facility Receives FAA Repair Station Certificate

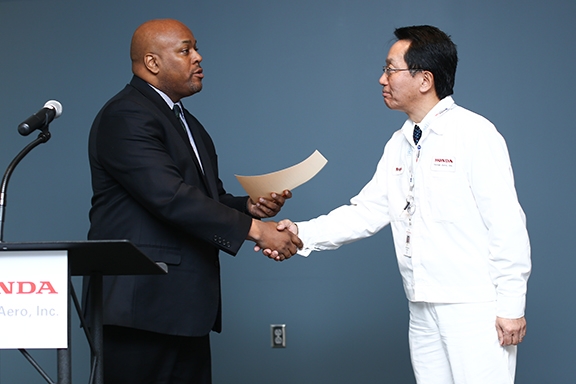

Honda Aero President Atsukuni Waragai accepts the PART 145 repair station certificate from FAA representative Jeffrey Phipps

The Honda Aero, Inc. (HAI) HF120 turbofan engine production facility in Burlington, North Carolina, has officially received a PART 145 repair station certificate from the US Federal Aviation Administration. This FAA certification paves the way for HAI to act as the dedicated Maintenance, Repair and Overhaul operation for the GE Honda Aero Engines HF120 Platform, the same engines that are used in the company’s HondaJet.

HAI had already received its FAA Production Certificate for the HF120 turbofan engine back in March of last year, but now the facility will also be able to provide maintenance, repair and overhaul service to customers. In addition to powering the HondaJet, which began deliveries in December of 2015, the HF120 is also available for other airframe applications.

“This is a significant milestone for Honda Aero made possible by the challenging spirit of our team of associates,” said Honda Aero President Atsukuni Waragai. “By combining production and maintenance operations on one campus we will better serve our customers of today and tomorrow.”

Because the Honda Aero, Inc. Maintenance, Repair and Overhaul operations share space in the same Burlington production facility with the engine manufacturing operations, MRO engineers will be able to provide feedback regarding the engine’s in-service performance to the engine design and production team.

According to Honda, in addition to the engine assembly and MRO operations, the Burlington plant boasts a parts warehouse and state-of-the-art test cell.

The News Wheel is a digital auto magazine providing readers with a fresh perspective on the latest car news. We’re located in the heart of America (Dayton, Ohio) and our goal is to deliver an entertaining and informative perspective on what’s trending in the automotive world. See more articles from The News Wheel.