Lithium-metal batteries have long been considered the next big advancement in energy storage, offering nearly double the energy density of today’s lithium-ion packs. But they’ve been held back by a persistent issue—dendrites. These tiny, tree-like metal formations grow inside the battery during charging, often piercing internal components and leading to short circuits or fires. Despite the promise of superior performance, this flaw has kept lithium-metal designs largely in the lab.

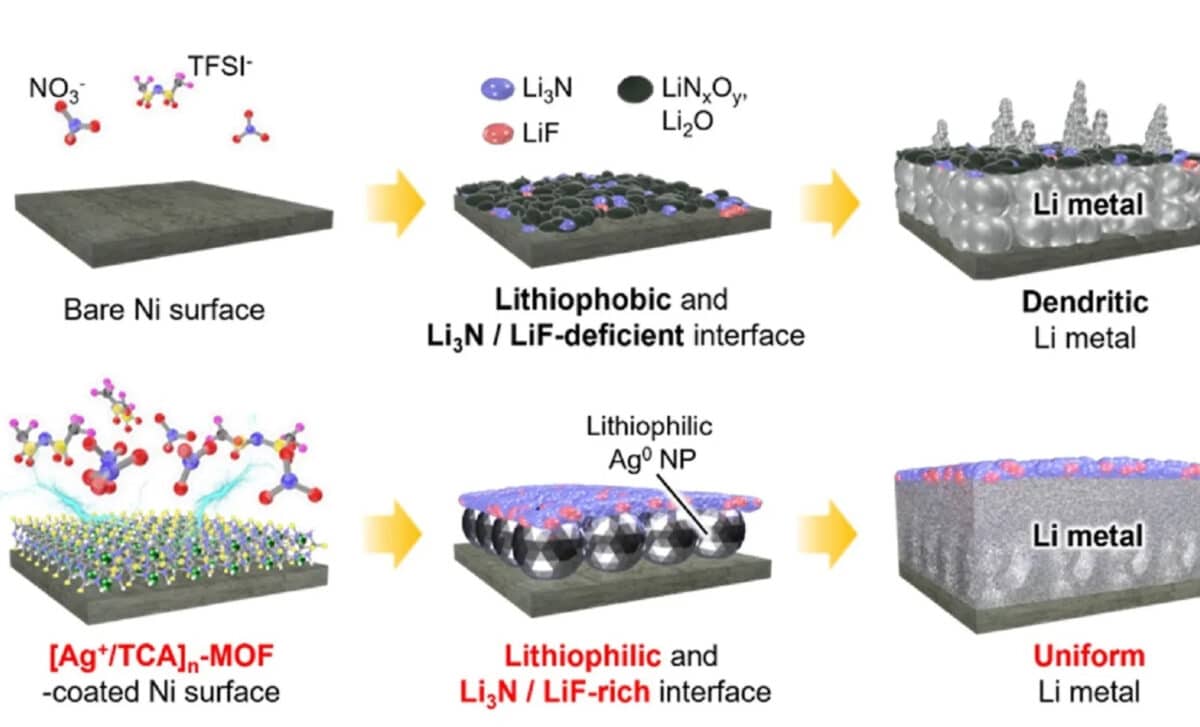

That’s now changing, thanks to new work led by Professor Cho Jin-han and his team at Korea University. Their approach adds a microscopic protective layer to the battery’s electrode, using alternating applications of silver ions and trithioisocyanuric acid (TCA). The goal is to guide lithium particles evenly during each charge and discharge cycle, preventing clustering and internal damage.

Silver Ions Prevent Dendrite Formation

The innovation hinges on what happens when the battery enters operation. The silver ions applied during production transform into nanoscale silver particles. These particles act like directional markers, steering lithium atoms into an even distribution across the electrode. This smooth pattern prevents lithium from collecting into needle-like shapes—better known as dendrites.

At the same time, the TCA compound forms a secondary layer that is both strong and flexible. It protects the electrode from cracking, a common issue over long-term use. As noted by Supercar Blondie, the entire process was developed to work under normal air pressure and room temperature, without requiring high heat or complex manufacturing.

This simplicity could make the technology easier to implement in real-world production, bypassing some of the more expensive techniques used in next-generation battery designs.

Test Results Show Exceptional Stability

During lab testing, the Korea University team’s battery retained 96 percent of its capacity even after 1,300 full charge-discharge cycles. That figure represents a major leap over current lithium-ion technologies, which typically show noticeable degradation far earlier. The prototype also operated stably for more than 2,000 hours.

Such results suggest a significantly longer lifespan for EV batteries—an issue that continues to concern many potential buyers. Range anxiety is no longer the only sticking point; how long a battery stays efficient is now just as important. The researchers’ work directly addresses that concern by proving that lithium-metal cells can be stable over extended periods.

And they’ve done so using a technique that doesn’t introduce additional risks or complicated manufacturing demands.

Broader Potential Beyond Lithium

While the coating method was developed with lithium-metal batteries in mind, the research group believes it could also be applied to other metal-based battery chemistries, including sodium and zinc. That opens the door to a wider range of energy storage possibilities, each with its own benefits in terms of cost, abundance, and sustainability.

Many consumers still hesitate to switch to EVs due to lingering doubts about battery reliability and lifespan. If this technology can transition from lab to market, it could go a long way toward changing those perceptions—making electric vehicles more attractive not just for performance, but for longevity.

For now, the battery remains in the research phase, but the simplicity and effectiveness of the coating process make it a candidate for future commercial development.