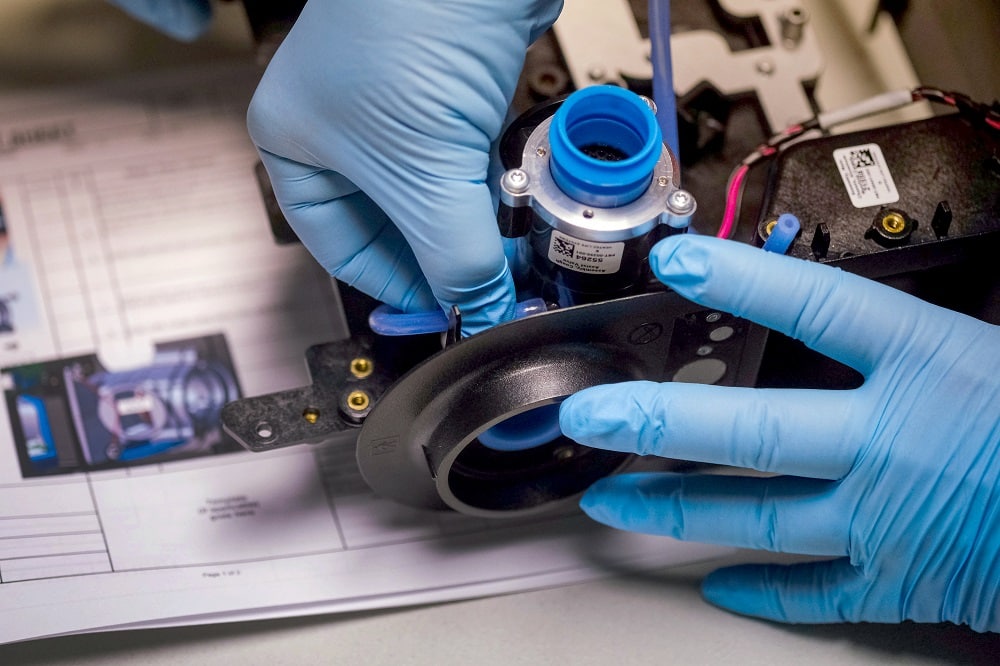

An employee undergoes training to build Ventec ventilators at GM’s Kokomo plant

An employee undergoes training to build Ventec ventilators at GM’s Kokomo plant

Photo: AJ Mast for General Motors

More than 1,000 workers at General Motors’ plant in Kokomo, Indiana, are transitioning into an essential new role: producing much-needed ventilators for critically ill COVID-19 patients.

In March, GM executives connected with Ventec Life Systems, a company that makes ventilators. The two companies quickly agreed to coordinate efforts and resources to ramp up ventilator production.

GM is using its network of suppliers to produce the needed parts and devoting its Kokomo plant to making the ventilators themselves. The goal: swiftly scaling up to begin production by mid-April.

GM’s OnStar Services: The best way to stay protected and connected

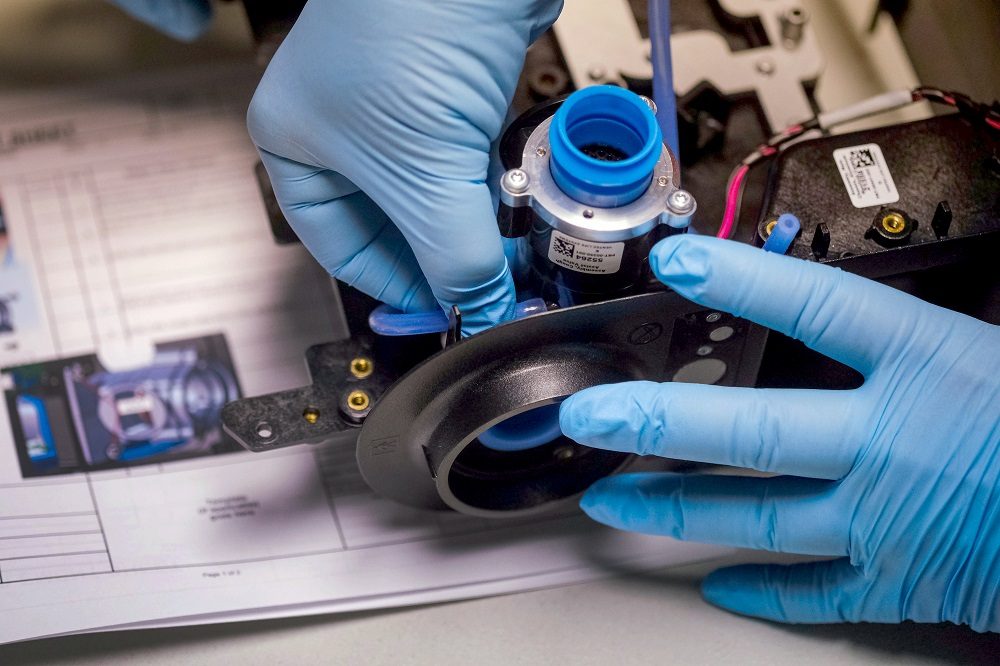

Photo: AJ Mast for General Motors

“Every ventilator we build can help save lives, and GM’s global supply base and manufacturing teams, the UAW, and the Kokomo community are working with passion and unwavering commitment to get the job done,” said Gerald Johnson, GM’s executive vice president of global manufacturing. “People have moved mountains to help increase production of Ventec’s critical care ventilator and we are just weeks away from delivering these lifesaving devices. I have never seen anything like it in my career.”

As part of this effort, GM is bringing together a team that will eventually number more than 1,000 people across three shifts at the Kokomo plant.

Employees there are receiving in-depth training on how to produce Ventec’s critical care ventilator model — and rigorous instruction on how to work with maximum safety in the midst of a pandemic.

Shop Click Buy: A great way to purchase a new vehicle without leaving the house

Photo: AJ Mast for General Motors

Upon arrival at work, each employee will have to sanitize his or her hands, undergo a temperature check, and don a medical-grade mask. Workstations will be at least 6 feet apart and occupied by only one worker. Cleaners will sanitize door handles and common areas at least three times each shift. Workers will have 30 minutes before and after their shift to clean their stations. Each shift will enter and leave through separate doors.

One of the most striking aspects of this effort is that GM isn’t requiring workers to come in. The Kokomo team consists of employees who signed up to offer their services instead of staying home. Once production is underway, they’ll be part of a massive campaign that should quickly yield up to 10,000 new ventilators per month for COVID-19 patients who desperately need them.

A longtime editor/writer and recently transplanted Hoosier, Caleb Cook lives in Xenia, Ohio. His favorite activities are reading and listening to music, although he occasionally emerges from the heap of books and vinyl records in his basement to stand blinking in the sunlight. Once fully acclimated to the outside world again, he can be observed hanging out with his wife, attempting a new recipe in the kitchen, attending movies, walking the dog, or wandering into a local brewery to inquire about what’s on tap. See more articles by Caleb.