Ford and Heinz Partner to Develop Sustainable Materials

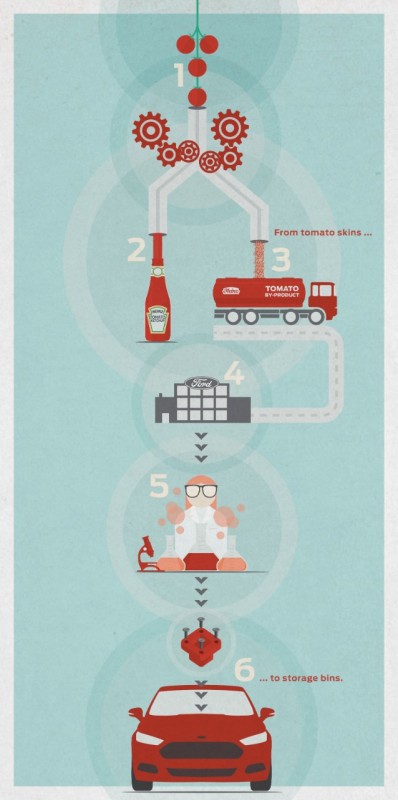

No, your cars won’t run on ketchup, but components of your cars may one day be built from dried tomato skins. That’s what Ford and Heinz are working to develop, at least.

Reportedly, researchers from Ford and Heinz are currently collaborating to see if tomato fibers could be used to develop composite, sustainable materials for motor vehicles. We’re not quite sure where they come up with this stuff, but apparently the two companies are hoping that dried tomato skins could be used for the wiring brackets in Ford vehicles or perhaps the storage bins used to hold things like coins and gum.

Related: Ford Files over 100 Patents for 2015 F-150

“We are exploring whether this food processing byproduct makes sense for an automotive application,” explained Ellen Lee, plastics research technical specialist for Ford. “Our goal is to develop a strong, lightweight material that meets our vehicle requirements, while at the same time reducing our overall environmental impact.”

This isn’t the first time that Ford and Heinz have teamed up. Almost two years ago, Ford collaborated not only with Heinz, but also with Coca-Cola, Nike, and Procter & Gamble in attempting to accelerate development of 100 percent plant-based plastic. These plastics could be used for any number of things—Ford names fabric and packaging as just two.

The partnership between Ford and Heinz is a perfect fit. Ford wants recycled materials to develop its automobiles, and Heinz has a whole bunch of peels, stems, and seeds from over two million tons of tomatoes that they use each year to bring us their ketchupy goodness—and nothing to do with ‘em.

“We are delighted that the technology has been validated,” said Vidhu Nagpal, associate director, packaging R&D for Heinz. “Although we are in the very early stages of research, and many questions remain, we are excited about the possibilities this could produce for both Heinz and Ford, and the advancement of sustainable 100% plant-based plastics.”

This isn’t Ford’s first foray into recycling. The company has spent several years exploring new ways to reduce, reuse, and recycle while also creating more efficient vehicles. This has led to such innovations as cellulose fiber-reinforced console components, coconut-based materials, and soy foam seat cushions, to name a few.

Related: Ford EcoBoost Sales Hit 500,000 V6 Engines Sold

The News Wheel is a digital auto magazine providing readers with a fresh perspective on the latest car news. We’re located in the heart of America (Dayton, Ohio) and our goal is to deliver an entertaining and informative perspective on what’s trending in the automotive world. See more articles from The News Wheel.