Ford Teaming with 3M, GE to Build Respirators

Ford announced on Tuesday that it will team with companies including 3M and GE Healthcare to bolster the production of medical supplies and equipment. This includes an exploration into whether Ford facilities can support the production of 3M’s powered air-purifying respirators and GE Healthcare’s ventilators.

“This is such a critical time for America and the world. It is a time for action and cooperation. By coming together across multiple industries, we can make a real difference for people in need and for those on the front lines of this crisis,” said Bill Ford, Ford’s executive chairman. “At Ford, we feel a deep obligation to step up and contribute in times of need, just as we always have through the 117-year history of our company.”

Collaborating with 3M on new respirator design

Team members from Ford and 3M are working together on a new powered air-purifying respirator design that uses parts readily available to both companies. This would include fans used in the cooled seats of the Ford F-150 and 3M HEPA air filters as well as portable tool battery packs. The objective would be for these PAPRs to be built at one of Ford’s Michigan manufacturing facilities in order to keep up with rising demand. Ford estimates that adding capacity for PAPRs to one of its plants could increase production tenfold.

Ford Service: New Police Interceptor Utility helps departments cut fuel costs

Building ventilators for GE Healthcare

Ford is also partnering up with GE Healthcare to produce simplified variants of the latter’s ventilators, which will be particularly crucial for patients with breathing problems caused by COVID-19. Ford intends to support production of these ventilators at one of its manufacturing facilities.

Producing face shields, 3D printing vital components

Ford is addressing another critical areas of need in testing transparent full-face shields intended for medical workers and first responders. These face shields can be used with N95 respirators to more fully protect people wearing them from COVID-19. Ford is testing out 1,000 of its shields at Detroit Mercy, Henry Ford Health Systems, and Detroit Medical Center Sinai-Grace Hospitals and intends to have 75,000 units produced by week’s end. Troy Design and Manufacturing, a Ford subsidiary, will produce over 100,000 face shields a week at its plant Plymouth, Michigan.

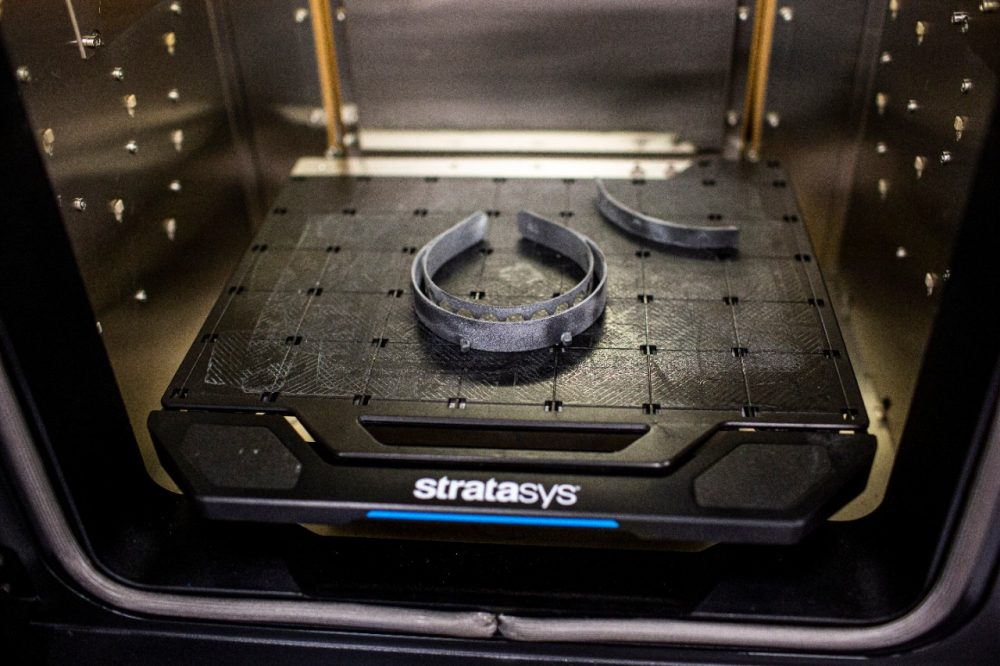

The Advanced Manufacturing Center in Redford, Michigan, will leverage its 3D printing capacity to generate components and subassemblies for personal protective equipment as well. Further, Ford has assembled a team committed to gathering surgical and N95 respirators and has pledged 40,000 surgical masks to Henry Ford Health Systems.

Ford CEO Jim Hackett says that Ford is communicating with officials from all levels of government to ensure that the company is aware of areas of need in the days ahead.

Ford’s Latest Vehicles: A look at the Ford SUV lineup

Kyle S. Johnson lives in Cincinnati, a city known by many as “the Cincinnati of Southwest Ohio.” He enjoys professional wrestling, Halloween, and also other things. He has been writing for a while, and he plans to continue to write well into the future. See more articles by Kyle.