Sometimes, it’s the invisible threats that worry drivers most. For all their benefits, electric vehicles still carry a mental image that can make even enthusiasts pause: the rare, yet dramatic, fires sparked by overheating battery cells. Videos of EVs engulfed in flames have circulated widely, often with little context, but enough to fuel unease.

In response to this lingering concern, a Chinese battery manufacturer, Svolt, has introduced a new technology it claims could reshape how fire risk is managed in EVs. The company’s latest innovation, the Dragon Armor 3.0 battery, is designed not just to prevent combustion, but to contain it if it does occur, before it reaches the cabin.

A Physical Barrier Between Electricity and Fire

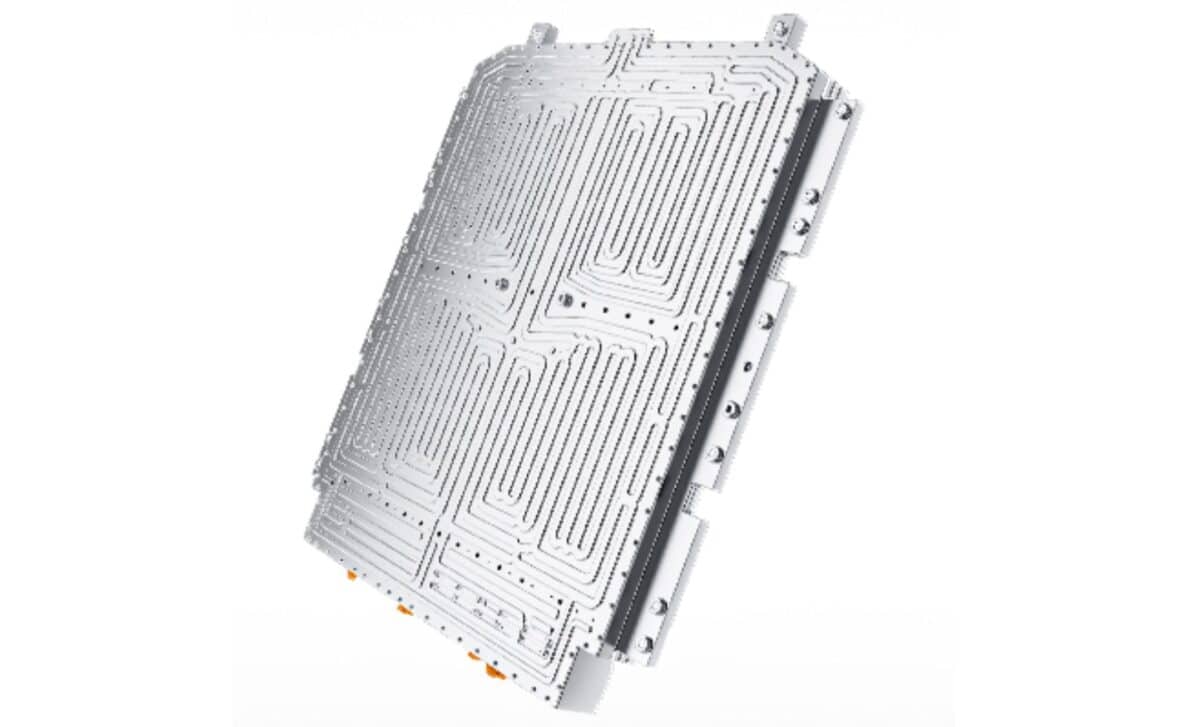

At the heart of this development is a concept Svolt calls “fire-electricity separation.” It’s a structural redesign of the battery pack: the electrical terminals and flame-release pressure channels are placed on completely separate paths. In practical terms, this means that if a single cell enters what’s known as thermal runaway, a chain-reaction overheating event, the heat and flames are directed downward and away from the passenger compartment.

Svolt says this is a first in the EV industry. By guiding pressure and combustion outward, the Dragon Armor 3.0 aims to neutralize one of the most feared scenarios in EV safety: a fire that breaks through the protective casing and reaches the cabin. In this case, the design could effectively act as a shield, buying valuable time for passengers and emergency responders.

Beyond Safety: Structural and Thermal Efficiency

Interestingly, this battery isn’t only about fire prevention. Svolt has paired its safety features with design elements that align with the broader industry shift toward more integrated vehicle architectures. The Dragon Armor 3.0 is compatible with CTC (Cell-to-Chassis) and CTB (Cell-to-Body) layouts, meaning it can be built directly into the structure of the vehicle, reducing weight and improving packaging.

Thanks to this integration, the usable volume of the battery pack increases without expanding its size. According to Auto Journal, energy capacity can rise by 7 to 10 percent, which can translate directly into longer range, always a priority in EV development.

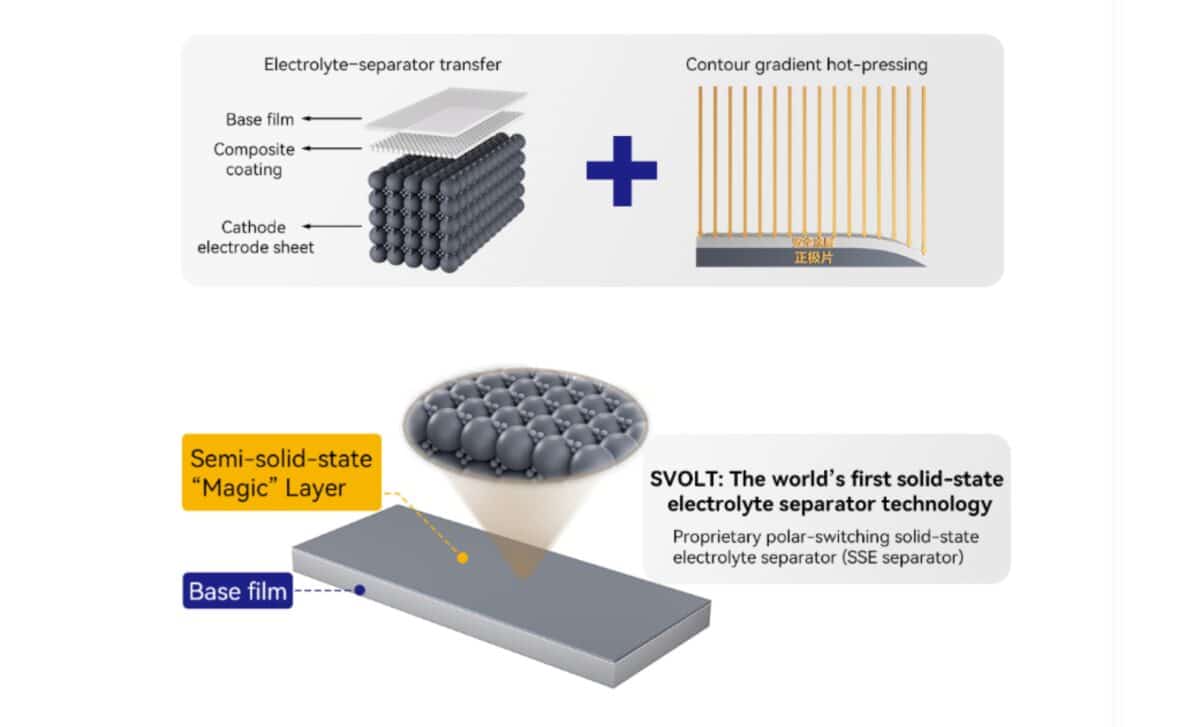

Improvements in Thermal Behavior

From a chemical perspective, the Dragon Armor 3.0 uses what Svolt calls a “liquid-solid” hybrid technology. While they haven’t disclosed exact formulations, the result is a higher threshold for thermal runaway: 5°C more resistance to ignition, a 10% increase in safety buffer time, and a 25% reduction in fire probability, based on internal testing.

Two capacity formats are planned: 86 kWh and 115 kWh, figures that place the battery in line with current long-range EV offerings. This would allow it to serve both midsize passenger vehicles and larger platforms, potentially including SUVs or vans.

An Arms Race for Safer Batteries?

Svolt isn’t the only player exploring this space. Competitors like CATL and BYD have also presented improved cell chemistries and designs to reduce thermal risks. Tesla, for instance, relies on a cylindrical cell format with internal fuses, while BMW (which has previously sourced batteries from Svolt) continues to develop its own safety standards as part of its next-gen EV platform.

In this context, Dragon Armor 3.0 is less of an outlier and more a marker of where the industry is headed. The challenge is no longer just about making batteries more powerful, it’s about making them structurally smarter and more resilient under stress.