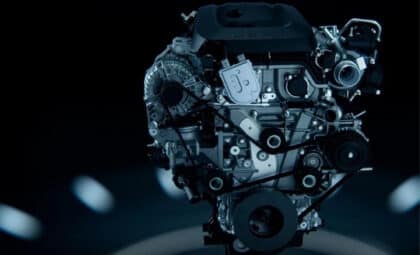

The automaker’s upcoming ZR15DDTe engine features cold-sprayed valve seats, a departure from conventional press-fit methods, aiming to push thermal efficiency to an industry-leading 42 percent.

This breakthrough comes as part of Nissan’s third-generation E-Power system, which uses a small internal combustion engine strictly to generate electricity, while an electric motor powers the wheels. According to Motor1, the innovation is meant to optimize airflow and combustion performance, raising efficiency without adding mechanical complexity.

After facing setbacks with its previous VC-Turbo engine due to durability issues and recalls, Nissan appears to be taking a more cautious yet ambitious route. Rather than adding new systems, the automaker is redesigning familiar components with a focus on manufacturing precision. The new hybrid engine is expected to debut in the next-generation Rogue, slated for 2027.

Cold-Spray Manufacturing Arrives in Mass Auto Production

Cold spraying is not new in industrial contexts, but its use in large-scale automotive manufacturing marks a significant step. Nissan uses a copper-based alloy sprayed at supersonic speeds onto the cylinder head, creating the valve seats directly onto the component instead of inserting them separately. The technique allows for reshaped intake ports that reduce air turbulence, contributing to optimal combustion flow.

As Motor1 reports, the resulting geometry enhances tumble flow—a specific air motion in the combustion chamber linked to greater thermal efficiency. This detail is critical, since the design cannot be applied to existing cylinder heads; it requires a completely new casting tailored to the sprayed material. Nissan received the patent for this technology in April, after applying in 2020.

Improved Thermal Efficiency Edges past Rivals

Nissan claims a thermal efficiency of 42 percent for the ZR15DDTe engine, a figure that places it ahead of Toyota and Hyundai, both of which have reached the 41 percent mark with their own hybrid engines. While still trailing the Formula 1 benchmark of over 50 percent—made possible with electric turbochargers—this level of efficiency in a production vehicle is notable.

The leap is not attributed to exotic fuel systems or experimental components but rather to refined engineering in existing parts. As mentioned by Nissan, the copper alloy used has high thermal conductivity, which helps with valve cooling and overall engine temperature regulation. That allows for more aggressive tuning without compromising durability.

A Different Approach after Vc-Turbo’s Failure

Nissan’s VC-Turbo engine, once hailed as a game-changer for its variable compression technology, failed to live up to expectations. The added mechanical complexity led to widespread reliability issues, forcing the company into a large-scale recall and tarnishing the reputation of its engine development program.

This time, the strategy is markedly different. No moving parts have been added; instead, the company is changing how parts are made. By rethinking the role of valve seats, a small yet critical component, Nissan hopes to sidestep the pitfalls of mechanical overengineering. As Motor1 points out, this decision stems from lessons learned rather than speculative ambition.