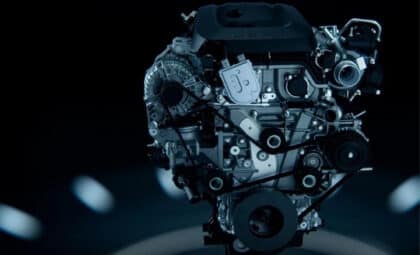

Photo: © General Motors

If you stay up to date on upcoming vehicles, chances are you’ve probably come across the word “tooling.” Let’s take a closer look at exactly what this term means and its unique role in the auto production process.

New Tires: Simplify the search with this helpful tool

[wptab name=’#1′]

Tooling defined

Tooling is simply the process of designing and engineering the tools used to manufacture components. So, in the car industry, tooling has to do with specifically designed tools that automakers use to forge vehicle parts.

Why it’s important

Although tooling has long been a crucial part of auto production, today’s market is transitioning from high-volume and low-mix to low-volume and high-mix auto production. To put it simply, one tool could produce several different parts, in the past. Now, a unique tool is required to make each part of a new car.

Manufacturers are also releasing new models and redesigned ones at a faster rate than they did previously. So, the companies which create these tools must boost their efficiency to meet this increased demand for more tools.

[wptab name=’#2′]

Manufacturing processes

Due to the wide spectrum of tools used in modern manufacturing, there are a few different types of manufacturing that an auto part can undergo. For example, CNC Milling (or machining) is a production method that involves batch manufacturing of parts. Workers feed raw material to the machine, then the machine triggers automatic processes to coin the parts. Engine cylinder heads, transmissions, gearbox cases, flywheels, engine locks, wheels, and water pumps are just some of the parts that rely on this type of manufacturing.

Yet another process is called “turning.” This is where a turning machine or lathe machine forges rotational parts by removing unwanted components during production. The machine also carries out axial drilling, reaming, boring, and tapping functions. Brake drums and rotors are two parts made using this process.

[end_wptabset]

Stunning Strength: Meet the 2018 Chevy Truck Lineup

News Sources: AutoForm, Dawson Shanahan, Bhavya Machine Tools

The News Wheel is a digital auto magazine providing readers with a fresh perspective on the latest car news. We’re located in the heart of America (Dayton, Ohio) and our goal is to deliver an entertaining and informative perspective on what’s trending in the automotive world. See more articles from The News Wheel.